Top Trends in Sheet Metal Fabrication CAD/BIM Services: What to Expect in 2023 - OFFSHORE OUTSOURCING INDIA

As a manager in the sheet metal fabrication sector, I am constantly on the lookout for new trends and technologies that will help our company enhance its operations and stay ahead of the competition. I have seen a tremendous shift in the use of CAD/BIM services in sheet metal design and fabrication over the last few years, and I am happy to highlight some of the top trends that we may anticipate seeing in 2023.

Offshore Outsourcing India to Other Countries With a competent workforce devoted to success, India is specific in CAD services for Sheet Metal Fabrication Outsourcing Services. We are dedicated to developing our global services while maintaining the Indian vision, and we cover all parts of the business, from basic drawing to towering structure design.

The rising usage of automation is one of the most significant trends we are seeing in sheet metal fabrication CAD/BIM services. Sheet metal design services that are automated can save time and eliminate errors in the design process. Engineers may now produce sheet metal designs faster and more accurately than ever before thanks to automated sheet metal design services. We have already introduced certain automated design procedures in our business, with fantastic outcomes.

Another trend in Sheet Metal Design Outsourcing Services that we are seeing is the integration of artificial intelligence (AI) and machine learning (ML) technologies. Based on data-driven insights and analysis, AI and ML technology can assist engineers in refining their designs. We can use AI and ML technology to discover potential design flaws and make fixes before the manufacturing process begins. This technology has also proved extremely useful in streamlining sheet metal design for cost savings, material waste reduction, and overall product quality.

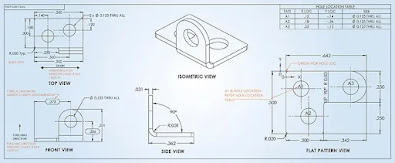

Sheet metal drawing services are another area where the adoption of CAD/BIM services has resulted in substantial improvements. Sheet metal drafting services used to be time-consuming and prone to errors. We can now develop more precise and comprehensive drawings faster than ever before thanks to CAD/BIM technology. We may also use CAD/BIM technology to produce 3D models that allow us to perceive the design before the manufacturing process begins.

Sheet metal design outsourcing has also grown in popularity in recent years. Outsourcing sheet metal design services can be a cost-effective choice for businesses that lack design talents in-house or require additional resources to accomplish their projects. Outsourcing sheet metal design services to a reputable partner can save time and money while also ensuring the finest quality designs.

The adoption of cloud-based platforms is another development in sheet metal design outsourcing services. Engineers may collaborate on designs in real-time from anywhere in the globe thanks to cloud-based systems. This technology has been extremely effective in boosting team communication and collaboration, particularly for firms with multiple locations.

Finally, sustainability has emerged as a significant problem in the sheet metal fabrication business, and we anticipate that there will be a greater emphasis on sustainable sheet metal design and manufacturing in 2023. By preparing material applications, decreasing waste, and reducing the environmental impact of the fabrication process, CAD/BIM services may play an important part in generating more sustainable designs.

The usage of CAD/BIM services in Sheet Metal Design Outsourcing Service and manufacturing has transformed the industry, allowing businesses to generate designs faster, more correctly, and sustainably than ever before. We are sure that the future of sheet metal production is bright, with trends towards automation, AI and ML, cloud-based platforms, and sustainable design. As a manager in this industry, I'm looking forward to seeing what the future holds and incorporating these trends into our operations in the coming years.

We have already begun to incorporate some of these trends in our operations at our company, and the results have been amazing. We have been creating designs for our clients using automated sheet metal design services, which has greatly decreased the time necessary for design work. We were able to figure out our designs for cost savings and material economy by applying AI and ML technology. This technology has changed the game for us, allowing us to develop more complicated and precise designs than ever before.

We've also used cloud-based platforms to work on designs with clients and team members from all around the world. Because we can share files, make changes in real-time, and keep everyone on the same page, this technology has improved communication and streamlined our design process.

Another exciting trend in Sheet Metal Design Outsourcing Service and production is the use of virtual and augmented reality (VR/AR) technologies. We can generate virtual models of sheet metal designs using VR/AR technology, allowing us to examine the design and identify any potential flaws before manufacturing begins. This technology may also be used to produce virtual tutorials of the manufacturing process, allowing us to anticipate possible problems and make changes before production begins.

We also stress sustainability, and we are constantly looking for methods to make our operations more ecologically friendly. Using CAD/BIM services, we were able to enhance our designs to reduce waste and reduce the environmental impact of the fabrication process. We've also been investigating the usage of environmentally friendly materials in our sheet metal designs, such as recycled metals and alloys.

Automation, AI and ML, cloud-based platforms, VR/AR technologies, and sustainable design are the top trends in sheet metal manufacturing CAD/BIM services for 2023. As an industry manager, I am eager to watch how these trends will affect the future of sheet metal design and fabrication. At our company, we are dedicated to staying on top of current trends and adopting them into our processes to give the greatest quality sheet metal designs and fabrication services to our clients.

We discovered that adopting these trends into our operations has allowed us to stay ahead of the competition and give new and effective solutions to our clients. We have completed projects faster, more correctly, and more sustainably than ever before, resulting in greater client satisfaction and recurring business.

The capacity to develop highly detailed and accurate designs is one of the major advantages of employing CAD/BIM services in sheet metal design and manufacturing. We can picture every part of the Sheet Metal Design Outsourcing Service, discover possible flaws, and make modifications before manufacturing begins with 3D modelling. This technology has saved us a substantial amount of time and money because it allows us to detect and handle problems before they become costly blunders.

Another advantage of using CAD/BIM services is the ability to swiftly and efficiently build unique designs. We can generate custom sheet metal designs in a fraction of the time it would take working with traditional design approaches thanks to automated design technologies. This technology has enabled us to take on more projects and increase our expertise, which has aided in the growth of our company.

CAD/BIM services in sheet metal production are a rapidly rising trend that is updating the industry. Automation, artificial intelligence and machine learning (AI and ML), cloud-based platforms, VR/AR technologies, and sustainable design are just a few of the top trends that we may expect to see in 2023. As a manager in this business, I'm looking forward to seeing how these trends evolve and improve our operations. We are devoted to remaining on top of current developments and adopting them into our processes to give the finest quality sheet metal designs and fabrication services to our clients.

Check Our New Updates On The BIM and CAD Services:

1. https://offshoreout.blogspot.com/2023/04/how-to-choose-right-scan-to-bim-service.html

2. https://offshoreout.blogspot.com/2023/04/the-role-of-miscellaneous-steel.html

Comments

Post a Comment