3D Rebar Modeling vs. Traditional Rebar Detailing: Pros and Cons - OFFSHORE OUTSOURCING INDIA

We have vast experience in both 3D Rebar Modelling and traditional Rebar Detailing as skilled 3D Rebar Modellers. We have watched the evolution of the construction sector and the acceptance of new technology throughout the years. In this blog post, we will compare and contrast 3D Rebar Modelling and traditional Rebar Detailing, as well as examine their advantages and disadvantages.

Begin with Traditional Rebar Detailing. The process of preparing drawings that demonstrate the intricacies of reinforcement steel bars and the associated accessories is known as rebar detailing. These drawings, known as rebar shop drawings or rebar detailing drawings, are normally prepared in 2D style. Contractors and fabricators utilise the designs to construct the Bar Bending Schedule, which is a document that defines the number and length of bars necessary for the project.

Offshore Outsourcing India yields high-quality 3D Rebar Modelling Services both nationally and abroad, expressing strength, commitment, affordability, and effectiveness to meet the needs of our clients. Our goal is to form a mutually beneficial alliance that produces timely, well-organized, and profitable outcomes, distinguishing us from our competition.

As traditional Rebar Detailers, we have spent many hours by hand or with technologies such as AutoCAD developing these 2D designs. The process might take time, and mistakes are common. In 2D drawings, a lack of visualisation can also lead to confusion and misinterpretation.

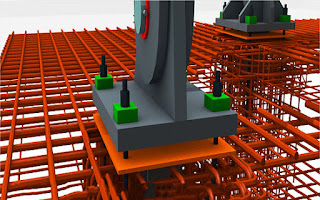

3D Rebar Modeling, on the other hand, is a method that entails producing a virtual 3D model of the reinforcement steel bars and associated accessories. Tekla, Revit, or AutoCAD 3D software is used to generate the model. Following that, the model is used to generate rebar shop drawings and a Bar Bending Schedule.

We have discovered that 3D Rebar Modelling has numerous advantages over traditional Rebar Detailing as 3D Rebar Modellers. First and foremost, 3D Rebar Modelling provides a far more thorough and accurate picture of the rebar than 2D drawings. This is because the model was developed in 3D, which allows us to observe it from all angles and make modifications in real time. Second, 3D Rebar Modelling lowers the possibility of errors and omissions. Because the model is created in a virtual environment, any errors can be easily identified and corrected before they are translated into the real world.

The ability to generate clash detection reports is another advantage of 3D Rebar Modelling. This means we can detect any collisions or impacts between the rebar and other construction elements like plumbing or electrical systems. This helps to avoid costly rework and building delays.

However, there are some disadvantages to 3D Rebar Modeling. The initial expense of integrating the curriculum and training the staff is one of the primary downsides. Furthermore, the software necessitates a high level of expertise and can be time-consuming to master. Finally, not all contractors and fabricators may be able to read and interpret 3D models, which may result in miscommunication and errors.

Both 3D Rebar Modelling and conventional Rebar Detailing have advantages and disadvantages. While 3D Rebar Modelling provides a more detailed and accurate representation of the rebar, it is expensive to put into place and requires substantial upfront expenditures. While less accurate, traditional rebar detailing is still widely used and can be more accessible to contractors and fabricators. Finally, the choice between the two will be determined by the project's specific objectives and requirements, as well as the team's budget and expertise.

As previously stated, 3D Rebar Modeling has several advantages over traditional Rebar Detailing. It is important to highlight, however, that the advantages of 3D Rebar Modelling extend beyond the design and detailing phases of the project. Contractors and fabricators can also examine and plan the installation process using 3D models. This is especially useful for complex projects since it helps the team to identify potential concerns and propose solutions before the start of construction. Furthermore, 3D models can be used to create animations and simulations, which will give stakeholders a better understanding of the project.

Another benefit of 3D Rebar Modelling is the ability to automate the generation of rebar shop drawings and Bar Bending Schedules. This decreases the time and effort required for manually developing these documents, freeing up energy to do other work. Furthermore, automated processes reduce the possibility of human error, which can result in costly mistakes and delays.

Despite the benefits of 3D Rebar Modelling, traditional Rebar Detailing remains popular in the construction industry. This is because it is a common and approachable strategy that does not necessitate considerable upfront fees or particular expertise. However, as the construction industry evolves and embraces new technologies, we anticipate an increase in the use of 3D Rebar Modelling.

Neither 3D Rebar Modelling nor Traditional Rebar Detailing has advantages and disadvantages. While 3D Rebar Modelling provides greater accuracy and representation, it necessitates a significant investment in terms of software, hardware, and expertise. Traditional rebar detailing is less precise but more accessible and cost-effective. Finally, the decision between the two methods will be influenced by the project's specific needs and requirements, as well as the team's budget and expertise. However, we believe that 3D Rebar Modelling is the future of the construction industry, and the rewards are well worth the investment.

It is vital to highlight that the advantages of 3D Rebar Modeling extend beyond the project's design and detailing phases. During the construction phase, the 3D model can be implemented to help with quality control and ensure that the reinforcement is properly fitted. This is especially true in complex projects where the rebar is intertwined with other construction components.

Furthermore, 3D Rebar Modelling can help with project management and construction site coordination. The project team can imagine the construction sequence and identify any issues that may develop during the construction process by using the 3D model. This reduces the likelihood of delays and rework, ultimately saving time and money.

In terms of sustainability, 3D Rebar Modelling can assist in the reduction of trash and the reduction of the environmental impact of construction projects. The amount of waste generated during the fabrication and installation process can be reduced by precisely modelling the rebar. This also reduces the need for extra materials, which might result in cost savings.

There are tonnes of benefits to using 3D Rebar Modelling over traditional Rebar Detailing. While there are some upfront costs for implementing the software and training the team, the advantages of 3D Rebar Modelling extend beyond the design and detailing phases of the project. 3D Rebar Modelling can increase accuracy, decrease errors, and give transparency and coordination throughout the construction process. As the construction industry evolves and embraces new technology, we anticipate a rise in the use of 3D Rebar Modelling.

Check Our New Updates On The BIM and CAD Services:

1. https://offshoreout.blogspot.com/2023/05/top-trends-in-sheet-metal-fabrication.html

2. https://offshoreout.blogspot.com/2023/05/top-trends-in-sheet-metal-fabrication.html

Comments

Post a Comment